Describe

|

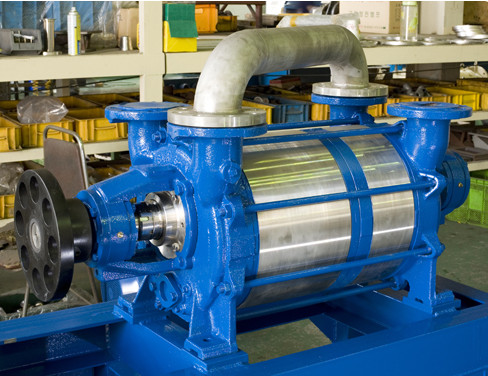

KLB (Feature & curve) |

KLS (Feature & curve) |

KLC (Feature & curve) |

KLD (Feature & curve) |

|

1.Various Model : More applicable to various optimized operation process than before. |

1. Double piston operation at one stage |

1. Using high efficiency screw profile |

1. Single Monoblock at one stage1단의 Monoblock 구조 |